Today's work on the RV-12 centers around the finishing of the wings. i started with installing the ailerons, then moved on to installing the landing light lense and wing walks nonslip covers.

Builder's note: The yellow tape helps hold the lens in place while installing the hardware.

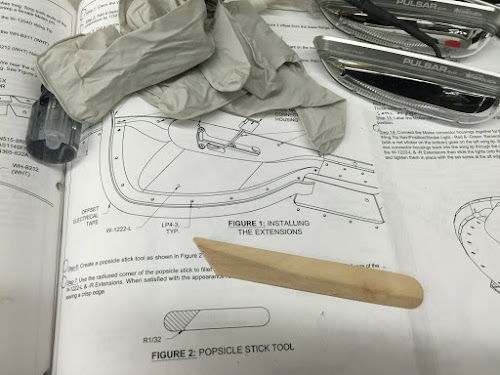

Reference: page 33-04

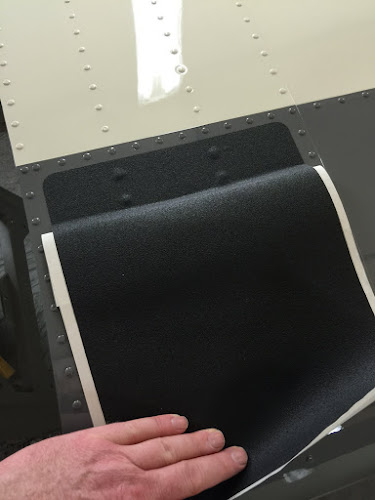

Note: I remove just a small strip of the backing to position the wing walk then worked my way up while removing the backing. Working the air out from around the rivets as I applied it.

This completes Section 30 and page 33-04.